The line pressure ratio typically needs to be determined experimentally. When using a hydraulic press for testing, the required static pressure needed to produce合格 (qualified) spherical shapes does not have theoretical comparability with the line pressure ratio—but it does show experimental comparability.

Determining the line pressure ratio should also consider another key factor: the design philosophy behind the pellet press. Generally speaking, there are two primary design approaches for pellet presses:

1. Achieving high-quality pellets and maximizing production capacity by using a high line pressure ratio (which results in narrower压辊 widths at the same total pressure) combined with high rotational speeds.

2. Producing qualified pellets and maintaining high throughput by employing a low line pressure ratio (leading to wider压辊 widths at the same total pressure) along with slower rotational speeds.

The ball-pressing machine itself is a non-standard piece of equipment, making it difficult to find a unified standard model—thus increasing the complexity of selection. Based on our experience, there may currently be the following common misconceptions during the selection process.

1. It is believed that the larger the diameter of the ball press machine, the higher the output will be.

This is true to some extent, but it’s not necessarily the case. Depending on the specific material being processed and the varying process requirements, the choice of pelletizer can actually differ significantly. In fact, in certain situations, a smaller-diameter pelletizer may not even have a lower processing capacity.

2. Believes that the higher the line pressure ratio of the ball press machine, the better.

In fact, the linear pressure ratio of the baling machine is the result of experiments aimed at achieving a specific process objective—only a reasonable ratio is optimal, as higher isn't always better.

3 people artificially classify the ball press machine.

For example, some pressing machines are categorized based on the material's moisture content—such as dry powder ball presses and wet material ball presses. Others are classified according to the compression ratio into low-pressure, medium-pressure, and high-pressure ball presses. Then there are machines tailored specifically for certain material types, like coal ball presses, coke powder ball presses, and mineral powder ball presses—and some even offer more specialized subcategories.

We believe that while reasonable classification can be useful, it’s not necessarily essential. However, classifications made purely for promotional purposes might inadvertently mislead investors in their decision-making process.

Two: Selection Criteria

When selecting a ball press machine, it's generally necessary to understand the following data:

1 Bulk density of the material, with specific density requirements for individual spherical particles

For a particular material, its bulk density is relatively constant. Some can be found in relevant reference materials, while others must be determined experimentally.

For the density of individual shaped pellets, it is determined by process engineers. In one scenario, the pellet press applies pressure at a fixed linear compression ratio—meaning the resulting density of the pellets directly matches the applied pressure. In another scenario, however, the process engineer aims to achieve a specific density target; for instance, with high-purity magnesium oxide, users may require pellets with an even higher bulk density.

2 Processing Capabilities

Here, processing capacity generally refers to the output of finally qualified pellets, not the throughput of material at the inlet of the pellet press. In fact, different pellet presses can yield varying pelletization rates even when processing the same material.

3-Sphere Geometric Dimensions

With the same material but different ball shapes, production output varies significantly—provided the pressure roller area remains unchanged. In other words, when a specific processing capacity is required, selecting the right equipment depends on the particular ball shape being used.

4. The required line pressure ratio for pressing qualified balls using the ball press machine

(1) The Basic Concept of Line Voltage Ratio

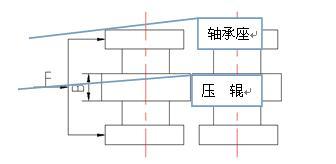

The linear compression ratio is an important parameter for characterizing the balling performance of a material, and it also serves as one of the key design parameters for pelletizing machines. Conceptually, it refers to the pressure applied per unit width of the pressing roller, as illustrated in the figure below:

The line pressure ratio is defined as: F/B, with the standard international unit being N/m. In engineering practice, it is commonly expressed as KN/cm or t/cm.

(2) Determination of the Line Voltage Ratio

The line pressure ratio typically needs to be determined experimentally. When using a hydraulic press for testing, the required static pressure to produce合格 (qualified) spherical shapes does not have theoretical comparability with the line pressure ratio—but it does exhibit experimental comparability.

Generally, using a ball-pressing testing machine to obtain linear pressure ratio data is relatively accurate.

Determining the line pressure ratio should also take into account another factor: the design philosophy behind the pellet press. Generally speaking, there are two main design approaches for pellet presses:

1. Achieving high-quality pellets and maximizing production capacity by using a high line pressure ratio (which results in narrower压辊 widths at the same total pressure) combined with high rotational speeds.

2. Producing qualified pellets and maintaining high throughput by employing a low line pressure ratio (leading to wider压辊 widths at the same total pressure) along with slower rotational speeds.

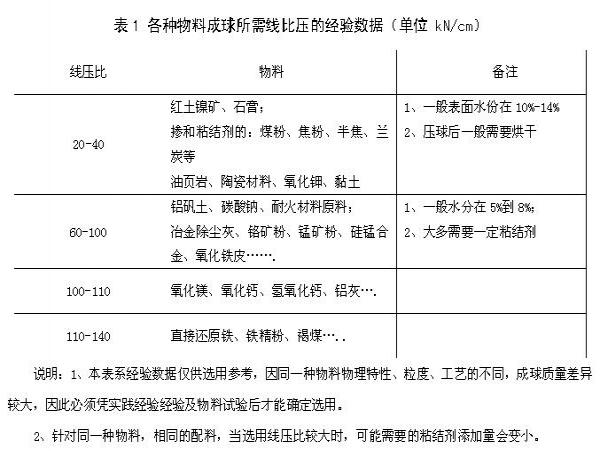

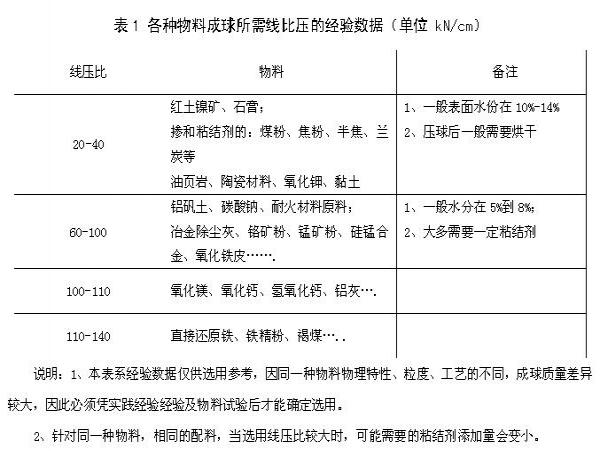

Many materials can also have their line pressure ratios determined through practical experience, as shown in the table below.

Three Selection Steps

1. Based on production capacity and line pressure ratio requirements, preliminarily select the press roller diameter using experience.

2 Accurately calculate the width of the press roller based on capacity requirements, the material's pelletizing performance (specifically considering the pelletization rate), the desired pellet size, and the corresponding press roller rotational speed for a given roller diameter.

3 Calculate the total pressure based on the computed nip width and the linear pressure ratio.

4. Select bearings for the ball press machine based on the total pressure.

5. Determine whether the diameter of the pressure roller is appropriate based on the bearing's geometric dimensions and the design dimensions of the bearing housing.

The principle for selecting the diameter of the pressure roller is to make it as small as possible, provided that the relevant geometric dimensions are still met. If the chosen pressure roller diameter is inappropriate, you’ll need to select a new one and repeat the calculations outlined above.

7. Once the diameter and width of the pressure rollers are determined, combined with the linear pressure ratio, the model and structural dimensions of the pellet press can be finalized.

The key point here is: how to determine whether the selection of the pressure roller diameter is appropriate.

There are still many important points to consider—find them all at Hongxin Mining Equipment Co., Ltd. We welcome your inquiry!